If your company sells products in packaging, there’s a regulatory shift happening that could significantly impact your bottom line. Extended Producer Responsibility (EPR) laws are rapidly expanding across the United States, making companies financially responsible for the collection, recycling, and disposal of their packaging materials. This isn’t just another compliance checkbox – it’s a fundamental change in how packaging costs are calculated and managed.

Are You a “Producer” Under EPR Laws?

The term “producer” in EPR legislation is broader than you might think. You’re likely considered a producer if your brand name or logo appears on product packaging, you manufacture products sold to consumers, you import packaged goods into the US, or you sell private label products under your store brand.

Revenue thresholds determine your obligations. California requires compliance from companies with $1+ million in packaged product sales. Colorado exempts producers with less than $5.5 million in revenue or those introducing under one ton of packaging annually. Oregon sets the bar at $5+ million total revenue or significant packaging volumes. Small business exemptions exist in most states, but the landscape is evolving rapidly.

What this means for your business: You’ll need to join a Producer Responsibility Organization (PRO), report packaging data annually, and pay fees based on the amount and type of packaging you use.

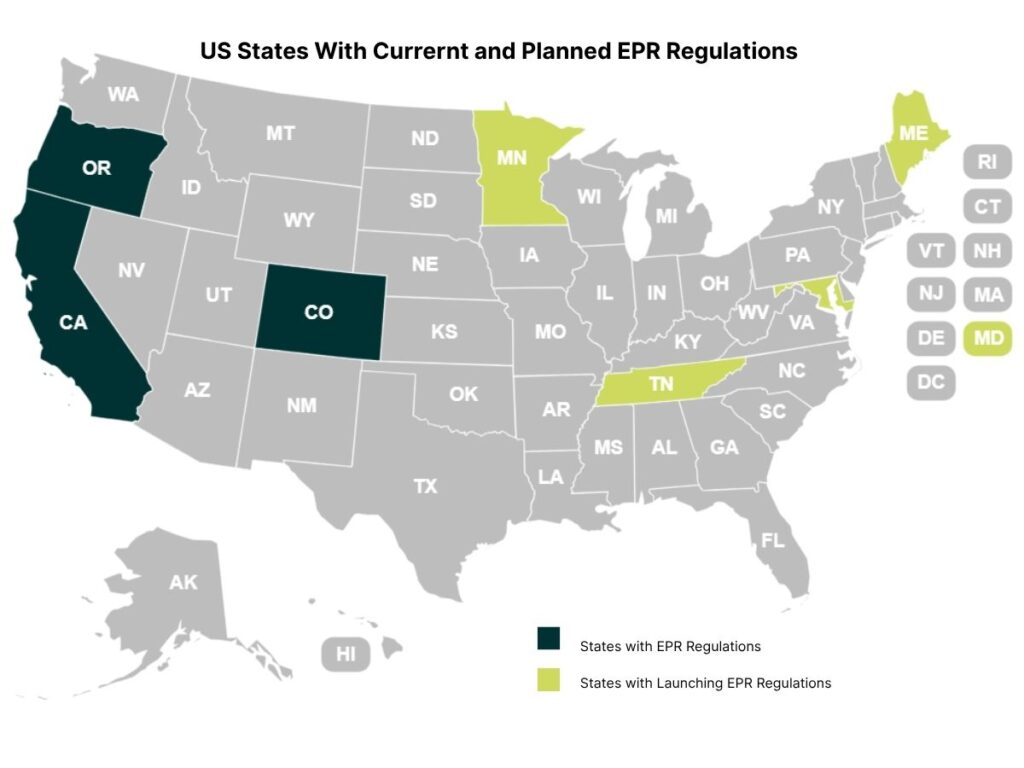

Which States Require EPR Compliance Now?

Active Programs Requiring Immediate Compliance

- California leads the charge with SB 54. While the final registration deadline is still pending, producers will be required to register within 30 days of regulation finalization. Data reporting will follow, and fees begin in 2026. A major requirement is also in place for a 25% plastic reduction by 2032.

- Oregon completed its first reporting period by April 30, 2025 (following a grace period extension from the March 31 deadline). Fees will begin in July 2025. The Circular Action Alliance (CAA) manages Oregon’s EPR program.

- Colorado required producer registration by October 1, 2024. The first data report is due August 31, 2025, and fees begin January 2026.

Programs Launching Soon

- Maine’s program begins in 2026, with the first reports due May 2027 and payments beginning September 2027.

- Minnesota requires PRO registration by July 1, 2026. Cost coverage begins in 2029, starting at 50% and increasing to 90% by 2031.

- Maryland passed SB 901 in May 2025, and implementation timelines are being finalized. Washington’s SB 5284 was enacted in April 2025, with producers required to align with a PRO by July 1, 2027.

- Tennessee’s EPR bill has been deferred until 2026, while New York’s Packaging Reduction and Recycling Infrastructure Act is pending Assembly consideration. Over 10 other states are exploring EPR legislation.

The takeaway is clear: if you sell products in multiple states, you’ll likely face EPR requirements in several jurisdictions with different rules and timelines.

How EPR Fees Work and How to Reduce Them

How EPR Fees Work and How to Reduce Them

EPR fees are typically calculated by the weight of your packaging materials (per pound), material type (plastic usually costs more than paper), and recyclability in local infrastructure. For example, 10,000 lbs of non-recyclable multi-layer plastic could cost significantly more than the same weight in recyclable cardboard.

Eco-modulation systems reward better packaging choices with lower fees. Materials that reduce your fees include high post-consumer recycled content, single-material packaging that’s easier to recycle, lightweight optimized designs, and paper and cardboard alternatives.

Conversely, materials that increase your fees include non-recyclable plastics, multi-layer films that can’t be processed, expanded polystyrene (banned in California), PFAS-containing materials, and black plastic that interferes with sorting equipment.

Cost Management Strategies

Step 1: Determine Your Obligations

Calculate revenue thresholds for each state where you sell, identify covered products in your portfolio, and understand reporting deadlines for each jurisdiction.

Step 2: Register and Report

Join the designated Producer Responsibility Organization (usually Circular Action Alliance), collect packaging data by weight and material type, submit annual reports by state-specific deadlines, and pay fees as calculated by the PRO.

Step 3: Optimize Your Packaging Strategy

Work with suppliers who understand EPR requirements, prioritize recyclable materials in packaging decisions, consider packaging reduction opportunities, and plan for future requirements like California’s 2032 targets.

What Packaging Materials Are Covered?

Consumer packaging is definitely included: food and beverage containers, product boxes, bottles and wrapping, e-commerce shipping materials, and shopping bags and retail packaging. Food service items like disposable plates, cups, utensils, take-out containers, and delivery packaging are also covered.

All material types fall under EPR requirements, including all plastic resins and films, paper, cardboard and paperboard, metal containers and components, glass bottles and jars, and composite and multi-material packaging.

Usually exempt materials include medical packaging (FDA-regulated sterile packaging), pharmaceutical containers with specific regulatory requirements, hazardous material packaging, pure B2B packaging that never reaches consumers, and reusable packaging in some states.

Materials Facing Restrictions

Several materials face bans or significantly higher fees. Expanded polystyrene (EPS) is banned for food service in California. PFAS-containing packaging is restricted in multiple states. Non-recyclable multi-layer films and PVC packaging face higher fees due to recycling challenges.

Your Action Plan: What to Do Now

Immediate Steps (Next 30 Days)

Assess your exposure by calculating revenue in EPR states. Inventory your packaging by listing all materials by weight and type. Check deadlines to identify upcoming registration and reporting requirements. Contact your packaging suppliers to ask about EPR-compliant alternatives.

Short-term (Next 6 Months)

Register with required PROs without waiting until deadlines. Implement data tracking systems for accurate reporting. Review your packaging portfolio for optimization opportunities. Budget for EPR fees in financial planning.

Long-term (6+ Months)

Develop a sustainable packaging strategy aligned with EPR goals. Partner with suppliers who can support compliance. Plan for expansion of EPR to additional states. Consider packaging innovations that reduce long-term costs.

The Bottom Line: EPR Is Here to Stay

Extended Producer Responsibility is rapidly expanding across the US. Seven states already have active programs, with more joining annually. The requirements will only become more comprehensive and widespread.

The businesses that succeed will be those that proactively address EPR requirements, optimize their packaging for both cost and sustainability, and build strong partnerships with suppliers who understand this evolving landscape. Don’t let EPR compliance catch you off guard – start planning now to protect your business and potentially turn regulatory requirements into competitive advantages through smarter packaging choices.

Need help navigating EPR compliance? Our packaging experts understand the requirements and can help you optimize your materials for both regulatory compliance and cost efficiency. Contact us to discuss your specific needs and develop a strategy that works for your business.