The Great Pallet Debate: Why Some Industries Are Going Plastic

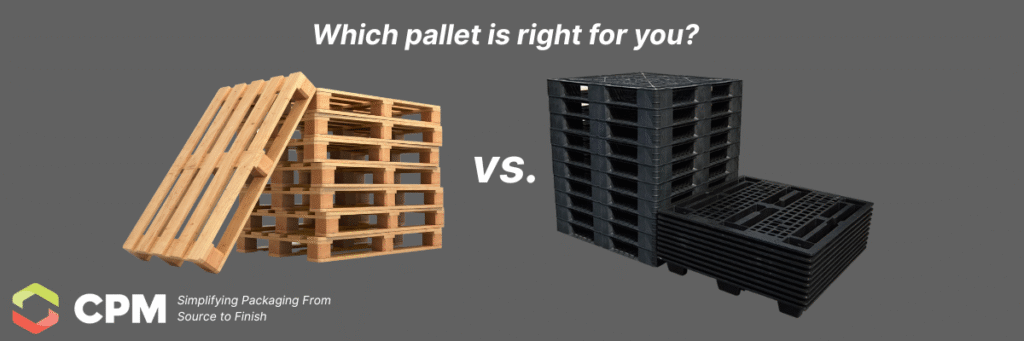

If you’ve ever worked in a warehouse, you know pallets are everywhere—those flat structures that move literally everything from point A to point B. Most people never think twice about them. But in certain industries, the choice between wooden and plastic pallets has become surprisingly controversial. Here’s why it matters more than you’d think.

The Humble Pallet’s Hidden Impact

Walk into any warehouse and you’ll see stacks of wooden pallets. They’ve been the go-to choice since the 1940s, and for good reason—they’re cheap, available everywhere, and get the job done. At $15-25 each, they seem like a no-brainer.

But here’s where it gets interesting. Some industries are quietly abandoning wood for plastic, despite plastic costing three to five times more. Why would anyone pay $75-150 for a plastic pallet when wood is so much cheaper?

The answer lies in the details that most of us never see.

When Clean Really Means Clean

Picture this: You’re shipping fresh strawberries from farm to store. Those berries sit on a wooden pallet that’s been who-knows-where, absorbed who-knows-what, and might be harboring microscopic guests you definitely don’t want near your food.

Wooden pallets are like sponges. They absorb liquids, odors, and yes, bacteria. In the food industry, where one contamination incident can trigger massive recalls, this isn’t just inconvenient—it’s potentially catastrophic.

Plastic pallets, on the other hand, are non-porous. Spill something? Hose it off. Need to sanitize? Hit it with industrial cleaners. They emerge from each cleaning looking exactly like they did on day one.

The Pharma Problem Nobody Talks About

Here’s something wild: many pharmaceutical cleanrooms ban wooden pallets entirely. It’s not about being picky—it’s about particles. Wood constantly sheds tiny fragments, invisible to the eye but definitely not invisible to quality control sensors.

Imagine manufacturing heart medication in a sterile environment, only to have wood dust contaminate your batch. That’s millions of dollars down the drain, not to mention the safety implications.

Plastic pallets don’t shed. They don’t splinter. They’re the strong, silent type that pharmaceutical companies have come to love.

Aerospace: Where Every Ounce Counts

The aerospace industry has its own quirky requirements. When you’re loading cargo onto a plane, weight calculations need to be precise. Here’s the thing about wooden pallets—their weight varies wildly based on moisture content. A “dry” pallet might weigh 35 pounds, but leave it in the rain and suddenly it’s pushing 70.

Plastic pallets weigh the same rain or shine. For an industry where fuel costs are calculated by the pound, this consistency isn’t just convenient—it’s essential.

The Money Talk Nobody Wants to Have

Let’s address the elephant in the room: plastic pallets are expensive. There’s no sugarcoating it. But here’s what the sticker price doesn’t show:

A wooden pallet lasts maybe 18 months with regular use. A plastic pallet? Try 8-10 years. Do the math over a decade, and suddenly that “expensive” plastic pallet starts looking like a bargain.

Then there are the hidden costs:

- International shipping? Wooden pallets need heat treatment (add $3-5 each)

- Product damage from splinters? It happens more than you’d think

- Labor costs? Plastic pallets are lighter, saving backs and time

- Storage space? Plastic pallets nest when empty, taking up 60% less room

The Green Question

“But wood is natural!” True. Wood is renewable and biodegradable. But when you’re replacing wooden pallets every year or two, that environmental impact adds up.

Most plastic pallets are made from recycled materials and can be recycled again at end of life. With their longer lifespan, you’re producing less waste overall. It’s not a clear-cut environmental win for either side, but plastic pallets aren’t the ecological disaster some assume.

Making the Smart Choice

So should everyone switch to plastic? Not necessarily. The decision depends on what you’re shipping and how often:

Plastic pallets make sense when:

- You’re in a regulated industry (food, pharma, aerospace)

- Pallets get reused frequently

- Cleanliness is critical

- You need consistent weights

- Automation is part of your process

Wood pallets still work for:

- One-way shipments

- Budget-conscious operations

- Non-sensitive products

- Traditional supply chains

The Future is… Complicated

The pallet industry is evolving. Smart pallets with GPS tracking, temperature sensors, and RFID tags are already hitting the market—mostly in plastic, since embedding electronics in wood is problematic.

As supply chains become more automated and regulated, the plastic pallet market continues growing. But wooden pallets aren’t disappearing anytime soon. They’ll likely coexist, each serving their niche.

The Bottom Line

Next time you see a pallet (and now you’ll notice them everywhere), remember there’s more to these simple platforms than meets the eye. The choice between wood and plastic reflects bigger decisions about cost, safety, efficiency, and sustainability.

For some industries, plastic pallets aren’t just an upgrade—they’re becoming essential. For others, good old wood still does the job just fine. The key is understanding your needs and making an informed choice.

Who knew pallets could be this interesting?